Membrane filters or commonly known as “membranes” are films that are microporous that have particular ratings of pore sizes. It is also known as a sieve, microporous filters, or screen. The membrane filters retain or filter particles that are larger than pore size. If there are particles that are smaller than pore size, then other mechanisms will be used. There are different types of membrane filters such as nylon, cellulose acetate, mixed cellulose esters or MCE membrane filter and so on. Here are more of the membrane filter types and their properties.

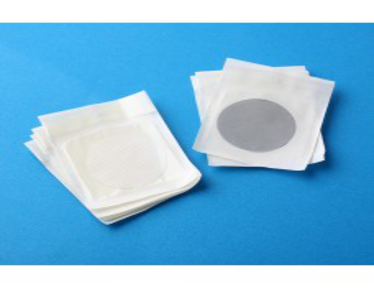

Mixed Cellulose Esters

MCE is composed of cellulose acetate and cellulose nitrate. It has high porosity that provides more flow rates. It also has protein binding at high levels that can be barred by pretreatment or application utilization. MCE is a standard membrane that is used in many lab applications such as filtering and sterilizing biological liquids, contamination analysis, microbiology, and air monitoring. This membrane can be turned transparent to see the particles collected in the filtration process.

Coated Cellulose Acetate

Coated cellulose acetate is composed of a cellulose acetate cast on a polyester support that is unwoven. It is characterized as non-fiber releasing capabilities and it has low levels of protein binding that is related to nitrocellulose. It also has low levels of static charge with chemically enhanced compatibility to weight alcohols at low molecular levels. Coated cellulose acetate is used as a pre-filter or a clarifying filter.

Hydrophilic PTFE

Hydrophilic PTFE has characteristics described as having maximum resistance to chemicals and pH levels. This membrane has flow rates at high levels with little aqueous extractables. When you wet the membrane with water, it is clear to the naked eye which makes it ideal to use in HPLC, organic solvents, and other aqueous mixtures.

Hydrophobic PTFE

The properties of a hydrophobic PTFE are that it is highly porous, thin, and it behaves like a total retentive membrane. It is also passive to most aggressive chemical solvents, bases, and strong acids. This membrane is applied by sterilizing gases to trap aerosols that are aqueous. It is also used in gas and air venting which enables the gases to move through the membrane freely while barring the liquids. This is so that critical samples and vacuum pumps are protected. Additionally, hydrophobic PTFE clarifies and sterilizes strong acids and other solvents that are incompatible to other membrane filters.

Nylon

Nylon membrane filters are made up by permeating a polyester web with a polymer that is made of nylon. This makes the membrane become durable, heat resistant, and fundamentally hydrophilic. Because that it is hydrophilic, it is suited for samples that are alcoholic and aqueous. This membrane filter can be used to sterilize, filter, and clarify organic-aqueous solutions.

Cellulose Acetate

This membrane filter is composed of a combination of diacetate and cellulose triacetate. It can be characterized as having high strength and a low charge of static. The benefits of using this are it can be sterilized repeatedly without losing its integrity or changing its bubble point. It has a relation to MCE membrane filter in terms of its increased solvent resistance to the molecular weight of alcohols at low levels. It also has better resistance to heat and its protein binding is lower. Cellulose acetate is applied to enhancing recovery of positive organisms and filtering enzyme solutions. It is also used on cytology diagnosis and studies on receptor binding.